There are many types of load cells suited to different applications, with unique strengths and weaknesses common to their basic designs. There may be multiple viable options when choosing what to use in a weighing application, but it is important to be mindful of some key factors in your considerations.

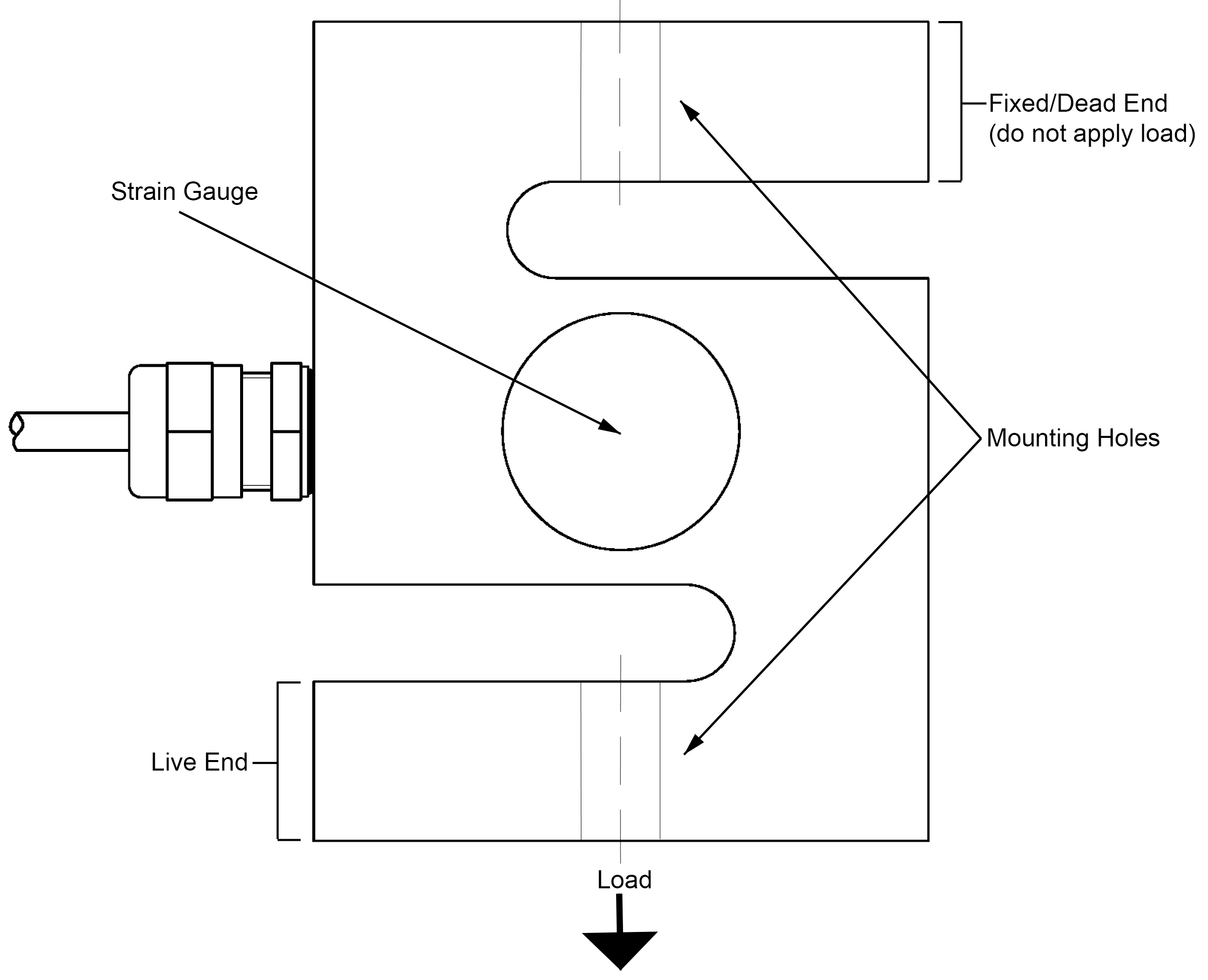

Single Point Load Cells

The most basic and versatile design; the single point load cell (sometimes referred to as having a “Dog Bone Sensing Section”) is conceived to receive compression force or applied load to a single point of measurement, hence the name. A platform may use a single unit of one of these load cells. The fixed end (with thread holes) is attached to a base. The live end is attached to a spider (load spreader) or top plate. The design and operational function of a single point load cell is also often referred to as a ‘symmetrical parallelogram,’ where two to three flexures deflect simultaneously.

“High Moment” single point load cells are secured at the live front-end, where an outboard hopper, or weigh head is attached, thus creating the high moment. Strain gauges are mounted within the sensing sections creating the Wheatstone Bridge measuring circuit, which provides the weight signal or output reading.

The single point design is suited for lower to medium capacity scales (<1t), offering a simple, easy-to-install, weighing solution with accuracy and tolerance for corner error. This load cell design is not utilized in high-capacity applications. For optimal performance, the top plate should not exceed the recommended platter size, specified per model (generally >1.2m x 1.2m) to assure off-center load accuracy and legal for trade compliance.

The single point type load cell is an easy-to-install weighing solution commonly found in bench or table-top scales, laboratory scales, counting scales, electronic balances, self-checkout scales, and especially in high volume OEM load cell applications.

Anyload produces high volumes of load cells of many shapes, sizes, and models each year, with a steady production flow of single point load cells, for OEM applications. We currently hold the world record for the highest accuracy and have been awarded the certificate of conformance for legal-for-trade load cells, at OIML C9, with the 651xx-series IP68/69K stainless single point load cell.

Beam Load Cells

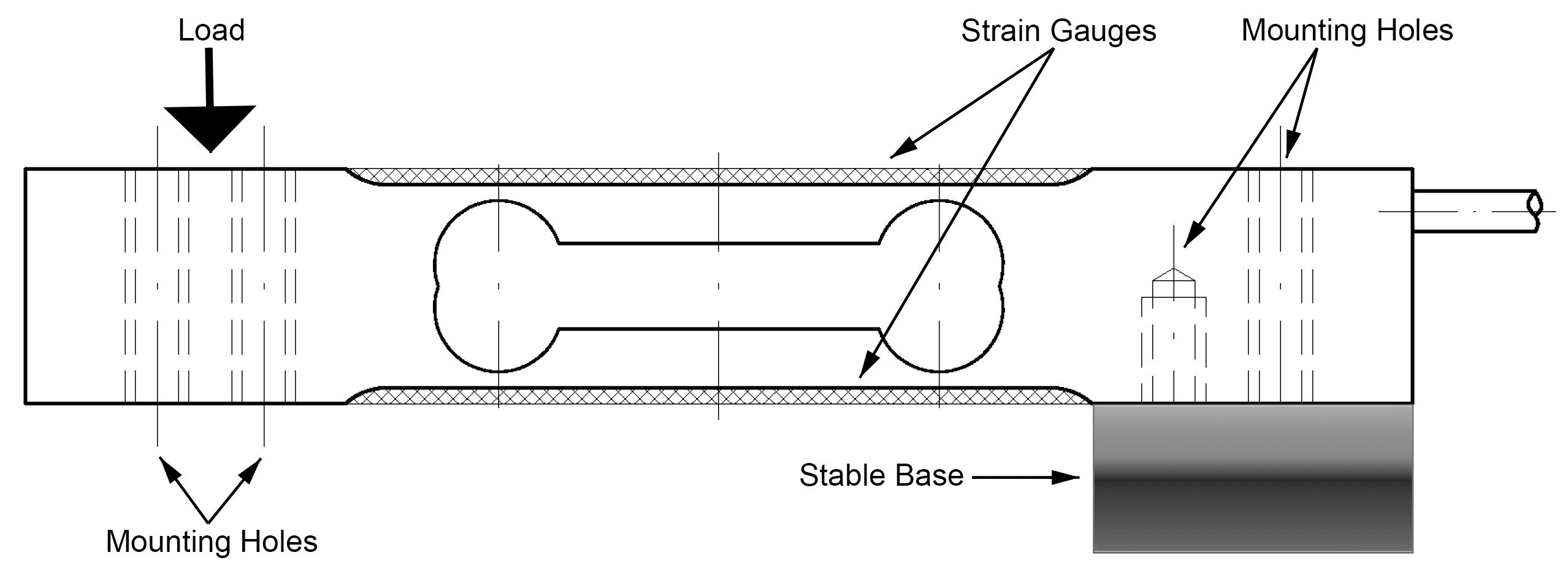

Single-ended beam load cells

Single-ended beam load cells are a broad category that includes bending beams and “true” shear beam designs, both of which share the same design function of having one fixed end and one live end for cantilever point loading. Although, unlike the single point, multiple-beam style load cells are commonly used in the corners of a weighing platform.

Bending beam load cells are usually suited to lower capacity (<0.5t) applications while shear beams tend to be used in higher capacity applications. The bending beam load cell is one of the most economical and popular lower-capacity (<0.5t) applications. It has a through-hole sensing section, and the strain gauges are installed on the inside of the hole, top, and bottom to measure bending force through the elastic deformation.

The “true” shear beam load cell (also known as “shear beam” or “cantilever” load cell) is generally used in higher-capacity applications. It has an I-beam “center web” design to measure shear force. The “true” shear beam design with a center web provides integrated torque and off-center load cancellation, thus reducing undesirable errors, as compared with the typical bending beam.

Single-ended beam load cells are cost-effective and flexible weighing solutions for a wide range of applications including floor scales, light-duty platform scales, hopper scales, and many legal-for-trade applications. Anyload has a wide range of OIML (500kg to 15t) and NTEP (250lb to 20klb) approved load cells. We also produce large quantities of OEM beam load cells each year.

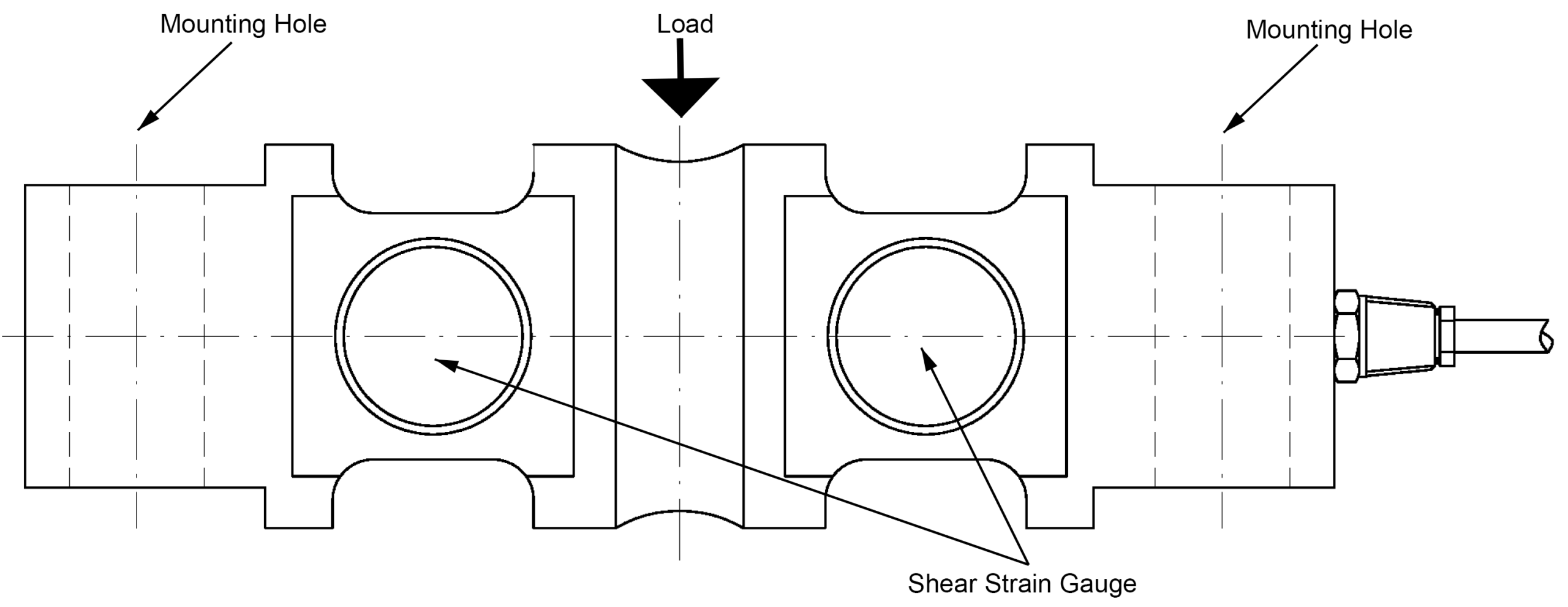

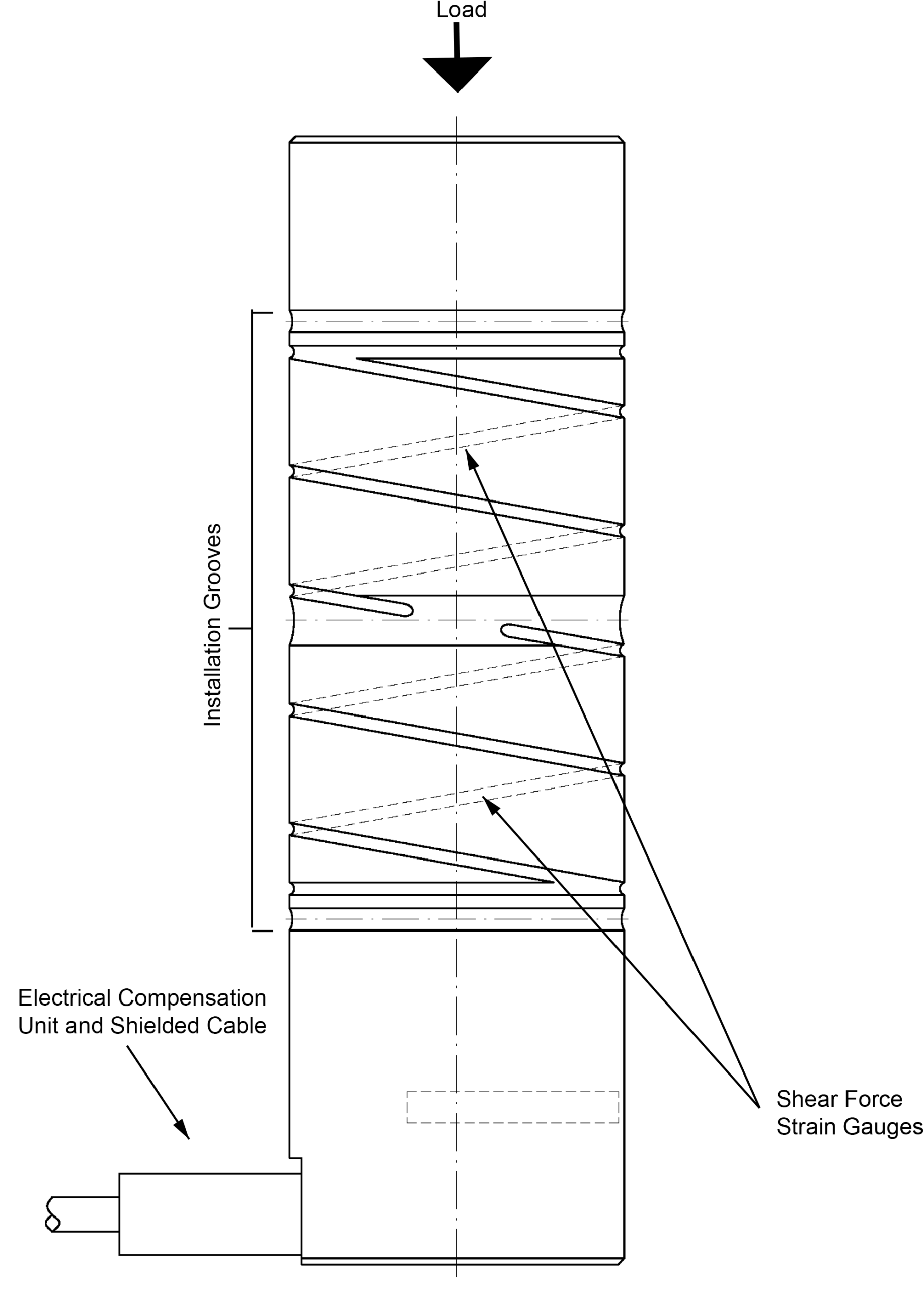

Double-ended shear beam load cells

The double-ended shear beam is similar in design to the single-ended shear beam. Unlike the single-ended shear beam, it is secured at both ends while force is exerted on the center of the beam structure. Shear force strain gauges are mounted in the middle surrounding the load application. Due to its design, it has natural cancellation of the bending moment after installation. This type of load cell is best suited to heavy capacity applications over 5t up to 100t per unit.

Common applications include truck scales, heavy hopper or tank scales, and many other industrial weighing applications. Anyload offers legal for trade double-ended beam load cells (OIML & NTEP) from 10t to 50t among other unique and interchangeable models.

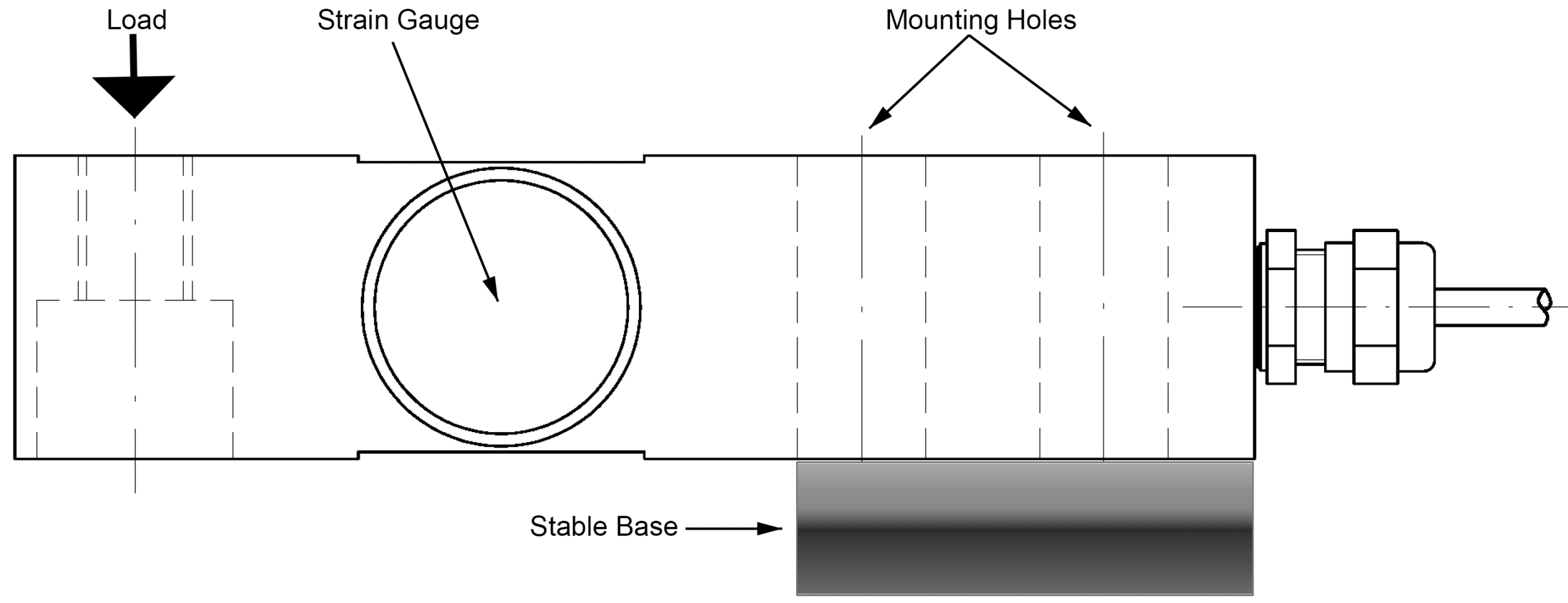

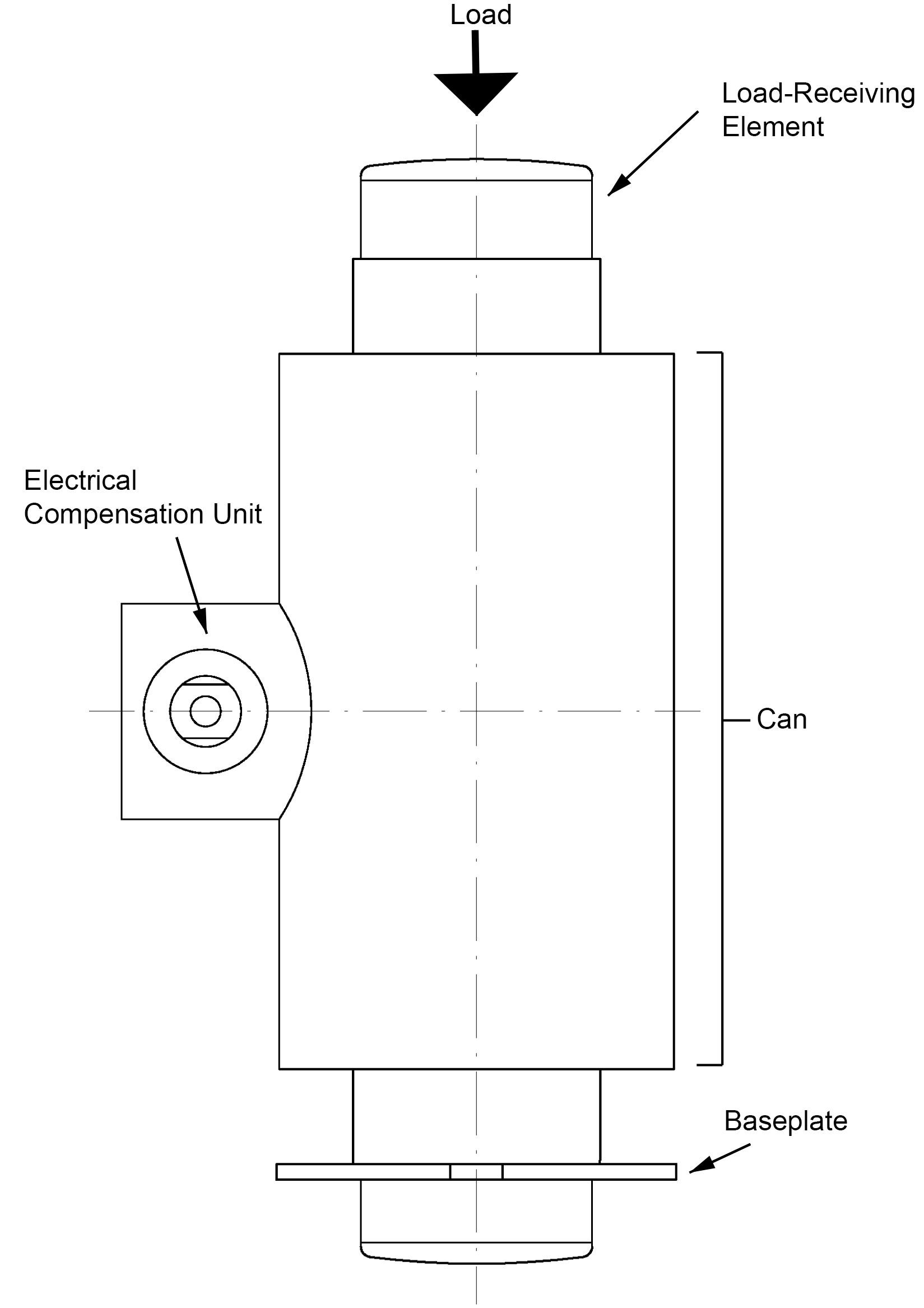

Canister Load Cells

A canister load cell is designed to measure compressive and tensile forces introduced centrally through its cylindrical column. A protective housing tube around the spring body has widened the cylinder, while the applied load force passes through the top and bottom ‘load button/base’ to a spring body where the strain gauges convert the momentary deformation of force into a precise electrical measurement.

The robust construction of these compression load cells makes them especially well-suited for high load capacity ranges exceeding 1 ton. The design is resistant to bending and side loads, making it ideal for situations with several directional load components where only one must be quantified. Canister load cells without top or bottom threads allow for side load protection and help avoid bending and torque influences. Common applications/industries include truck scales, agriculture, steel mills, large tank and hopper scales, railway car weighing, etc.

For capacities below 50t, Anyload’s canister load cells may appear similar to other competitors, but the internal structure is a patented design that achieves natural linearity with superior side load compensation and resistance to vibration, without the fragile linearity compensation of semiconductor gauges. Anyload manufactures legal for trade canister load cells from 10t to 50t capacities and OEM canister load cells for any capacity or requirement.

Disc Load Cells

Disc load cells offer a low profile, higher capacity solution while compensating well against side force (100% of capacity). Slightly lower cost, relatively lower accuracy, as compared to canister load cells, the core design is quite like a canister load cell. High-precision disc load cells offered by a select few manufacturers in the industry are commonly found in precision test machines utilizing hydraulic and/or screw-type machines in force measurement. In these cases, these certified disc load cells are used as a “secondary standard” to control the applied force of the machine and used to calibrate new load cells. Anyload’s 276EH is an economical compression load cell on the market and suitable for a variety of general-purpose applications.

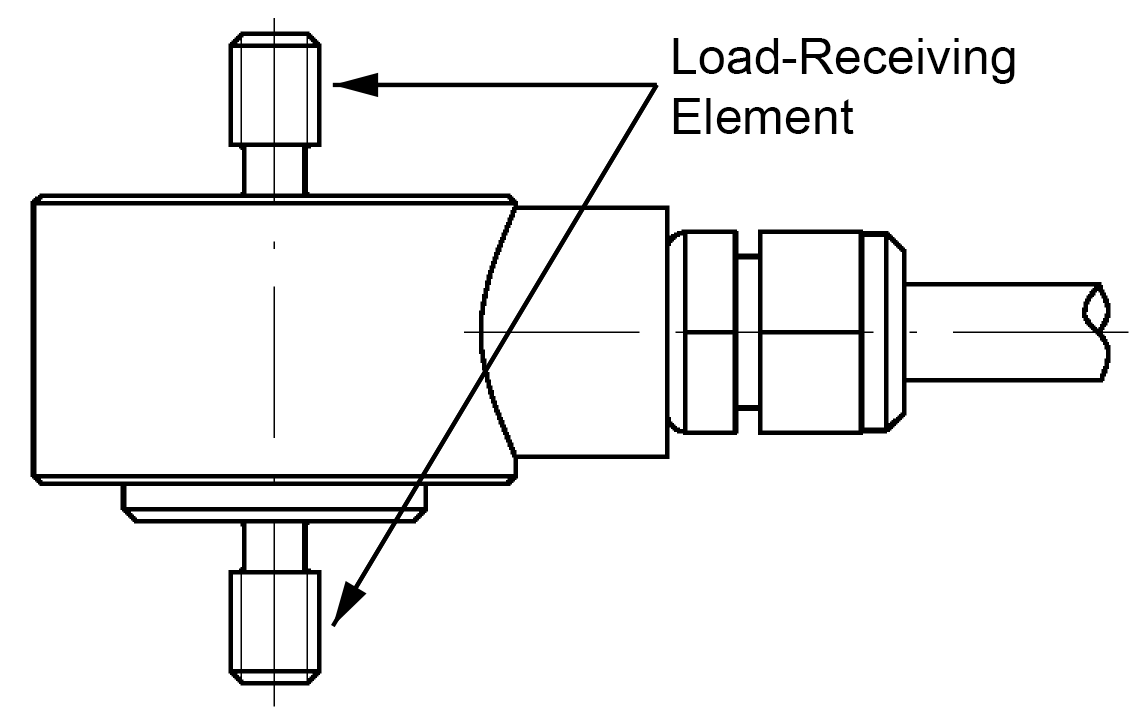

Load Pins

Load pins are designed for the measurement of tension or compression while directly integrated into the force flow without occupying additional space. Load pins can easily replace retention bolts or axles in existing applications. Since the design requirements are tailored to the situation, the exact dimensions of the load pin are critical.

Common applications are found across many industries, from steel mills, chemical plants, seaports, and logistics, anywhere where there are retention bolts or axels in existing applications usually for. Load pins are frequently used in providing safety checking for systems, and protection from overload, and are favoured wherever space restrictions and ease of integration are important.

Anyload offers load pins 10kg to 1,000t, however, due to the nature of this type of product, most load pins are manufactured to meet each customer’s performance needs and requirements. Most OEM load pins are made of high tensile stainless steel suitable for heavy-duty applications and exposure to chemicals, dust, lightning, or prolonged submersion in saltwater.

To order a customized load pin, please submit your requirements and specifications by filling up the Load Pin Order Form and our team will work with you to meet your needs.

Load Buttons

Load button load cells are designed for both tension and compression, especially where space and or weight are limited. By design, it is like the disc load cells, providing a compact solution where higher accuracy is not a primary concern. Common applications include robotics, professional sports equipment, medical equipment, and consumer electronics. For best performance and longer service life, the load should be applied without the presence of any side load or torque influence.

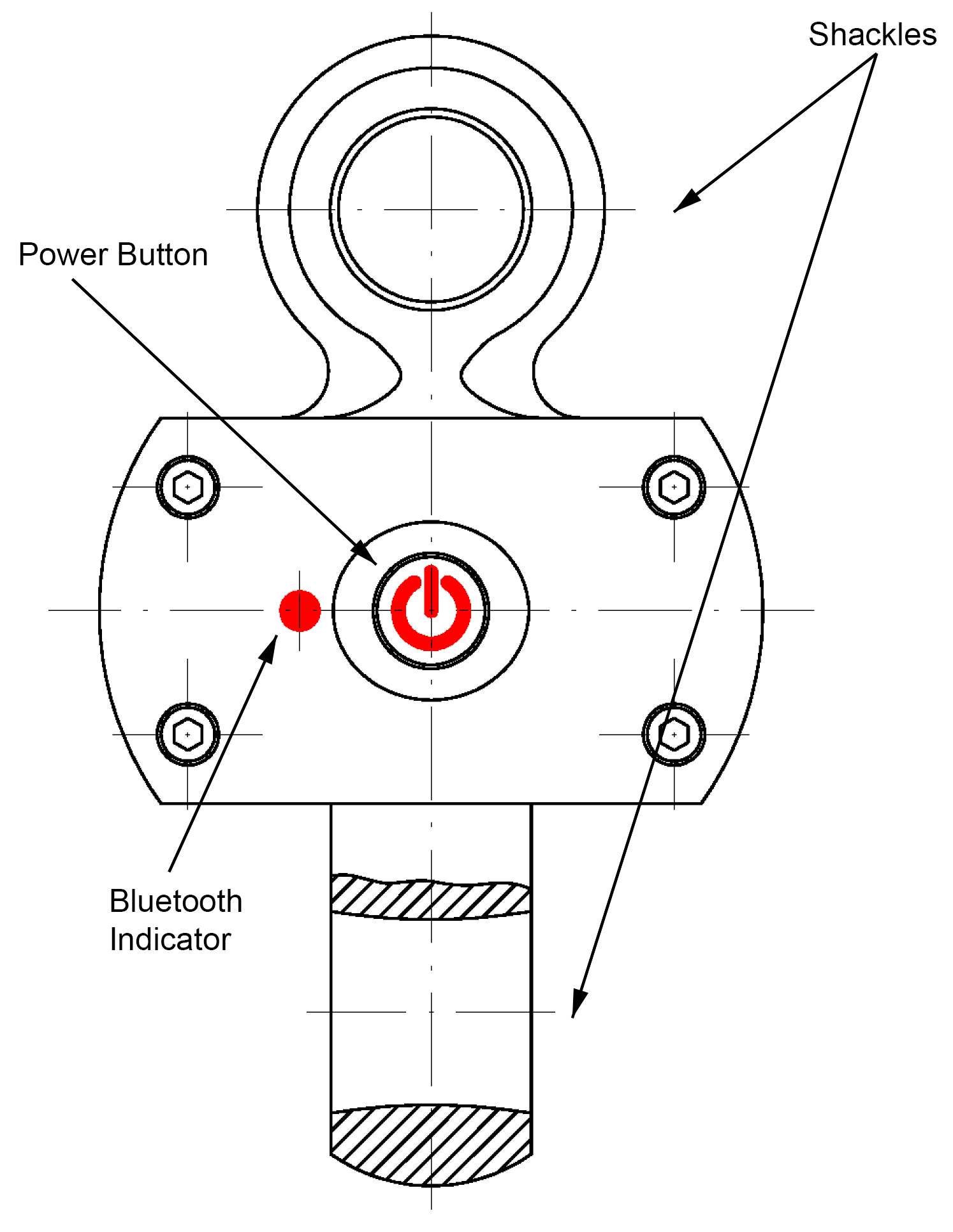

Tension Link Load Cells

The tension link load cell is in principle like a canister load cell. Traditionally, a column design with two shackles attached allows for easy installation. The tension link is resistant to bending moment and torque and is well suited for heavy capacity (>1t) situations. Common applications include fishing scales, construction and manufacturing, and cranes/suspended platforms. The tension link is often preferred over “S” type load cells for capacities over 2t and this is because the upper and lower female threads of “S” cells are vulnerable to wear and even failure at higher capacities.

Anyload produces the highest accuracy and most compact tension link load cells in the marketplace. Anyload’s tension links may appear similar to others in the marketplace, but our internal structure is a patented design that achieves natural linearity with superior temperature compensation and resistance to vibration. We hold the highest accuracy legal-for-trade certification, OIML C6 (10-50t), for tension link load cells. Extremely compact, heavy-duty, and high breaking force, we lead the industry in tension link performance.

S-Beam Load Cells

The S-beam load cell is a high accuracy, economical design that is suited for both tension and compression for low to medium capacity (<10t). They provide excellent side load rejection. For best performance, the load should be applied without the presence of such influence factors as bending force or torque and be complemented with superior quality rod-end bearings.

The S-beam load cell has a top and bottom threaded through-hole, allowing for easy installation. Larger capacity S-beams have a shear beam design that typically has a blind hole with an I-beam center web sensing section to measure shear force. In lower-capacity S-beams, the strain gauges are installed on the sides of a through-hole in a bending beam design. S-beam load cells are often used to suspend a weigh vessel, applying tension through stretching. Common applications of the S-beam include low-capacity crane scales, hopper scales, converting mechanical to electronic scales, any tension-compression force measurement, and test machines.